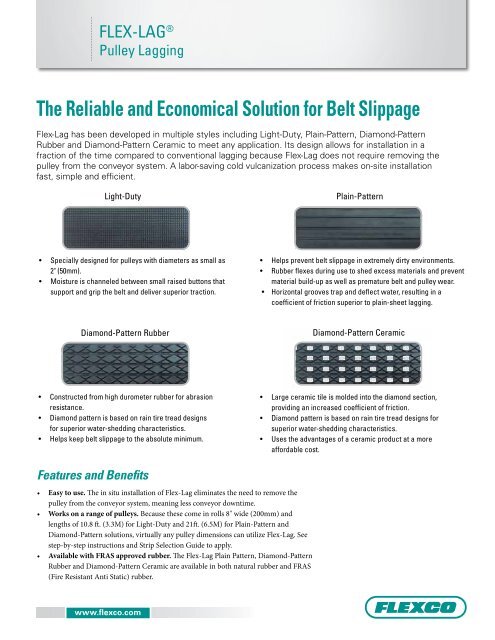

An example of such a condition is the pulleys on a bucket elevator where the pulleys operate within the enclosed elevator housing and material cannot be prevented from becoming trapped between pulley shell and belt.

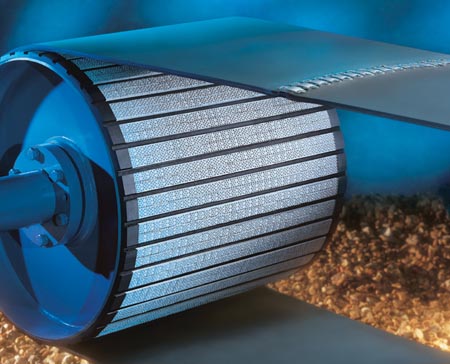

Flexco ceramic lagging.

To eliminate belt slippage increase pulley life improve water shedding and boost productivity flex lag bondable pulley lagging is a smart choice.

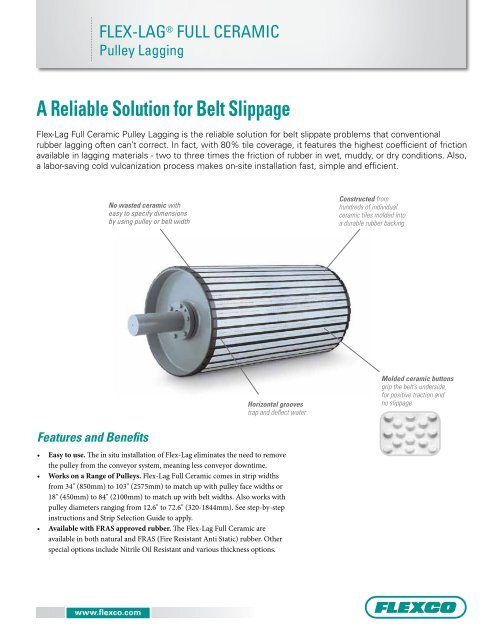

Flex lag full ceramic lagging is the reliable solution for belt slippage problems that conventional rubber lagging often can t correct.

83 hra rockwell hardness scale a.

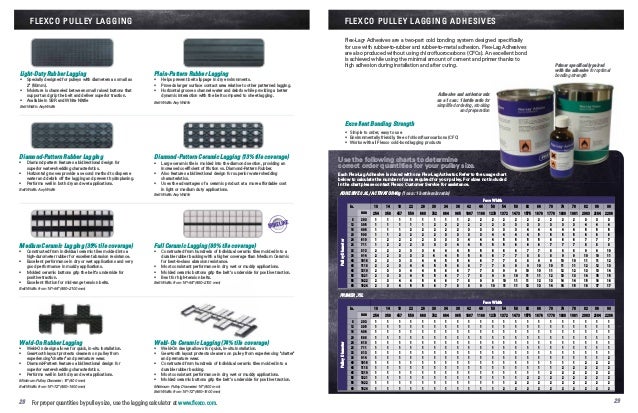

Flex lag full ceramic lagging fras rubber thickness belt width ceramic length strip length dimpled tile smooth tile.

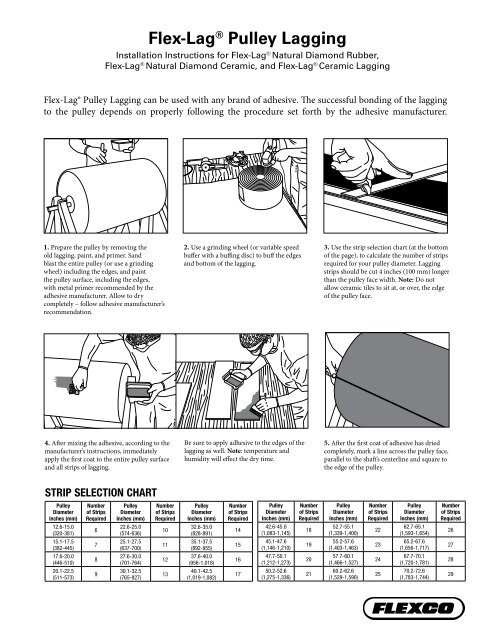

Enter your values below to calculate the appropriate number of strips rolls required for your application change to metric.

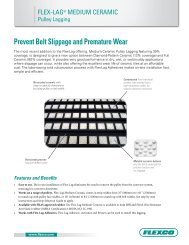

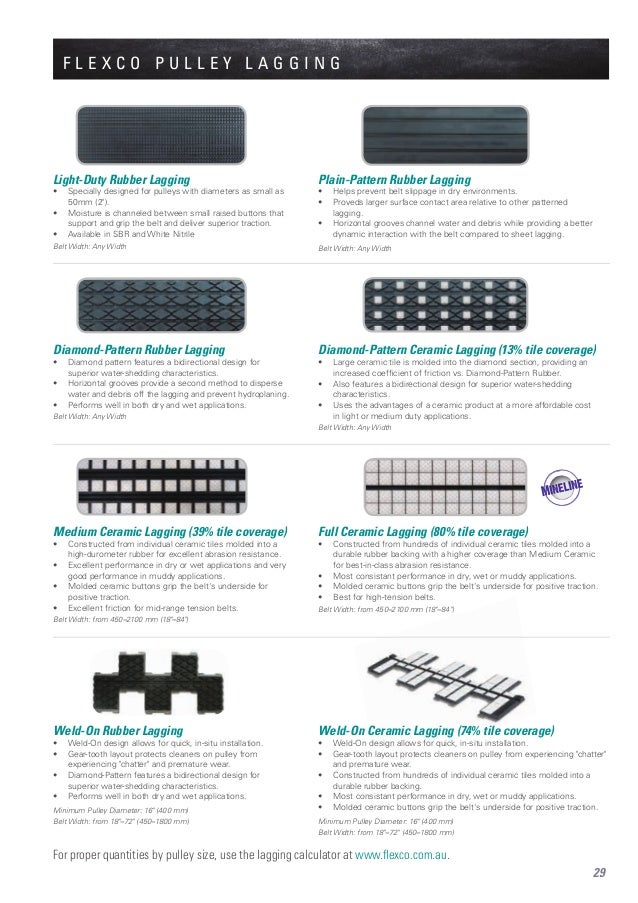

Flex lag diamond ceramic lagging has been developed to provide an alternative ceramic lagging option for low to medium tension conveyor pulleys providing the advantages of a ceramic product at a more affordable level.

Ceramic lagging or lining of a pulley is used in instances where the pulley operates in extremely aggressive conditions.

Flexco flexlag ceramic lagging installation instructional video english duration.

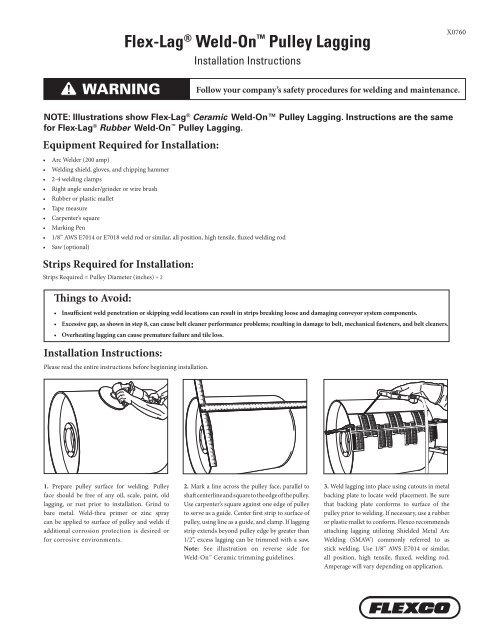

Installation use the flexco lagging calculator to determine the appropriate number of strips required for your application.

Flex lag diamond ceramic is specially designed to deliver the performance advantages of ceramic lagging at a much more affordable price.

Large ceramic tile is molded into the diamond section providing an increased coefficient of friction compared to diamond pattern rubber lagging.

Flex lag medium ceramic lagging featuring 39 coverage offers a lagging option between diamond pattern ceramic 13 coverage and full ceramic 80 coverage.

In fact with 80 tile coverage it features the highest coefficient of friction available in lagging materials two to three times the friction of rubber in wet muddy or dry conditions.

Isconsin aenue oners roe l sa tel.

Its design allows for installation in a fraction of the time compared to conventional lagging because flex lag does not require removing the pulley from the conveyor system.

Stainless steel welding tips tig welding duration.

Strip widths from 20 to 101 500 mm 2560 mm to match pulley face widths.